October 23rd, 2018

Case Study: The Greyhound Bridge

| Contract No: | 02/501/6877 |

| Client: | AE Yates |

| Location: | Lancaster |

| Value: | TBC |

| Summary: | 245m³ of Concrete Removed |

Background

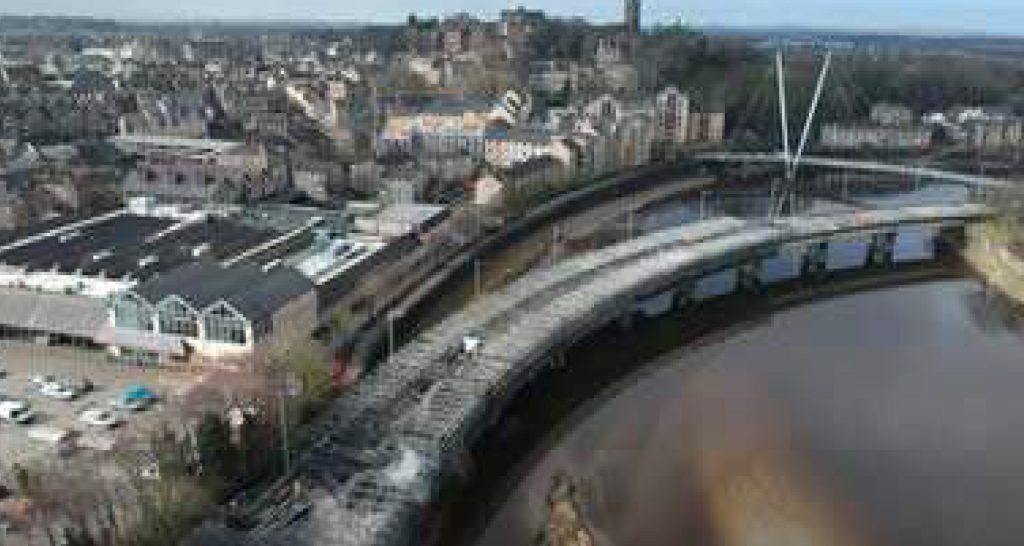

Greyhound Bridge carries the A683 (Greyhound Bridge Road) over the River Lune. It was constructed in 1911 as a railway viaduct and converted to a road bridge in 1972 with the addition of a reinforced concrete deck on top of the original steel construction. It has 9 spans, 8 piers and is 204.3m long and 12.66m wide. Lancaster’s Greyhound Bridge needs major

maintenance works to ensure it retains the strength to carry big HGVs.

The Scheme Involves

- Installation and maintenance of temporary traffic management

- Concrete repairs, including installation of galvanic cathodic protection

and, recasting of large areas at the joint positions - Replacement of buried joints

- Replacement of expansion joints

- Repainting of parapet, piers and superstructure

- Deck waterproofing

- Carriageway and footway resurfacing

- Maintenance repairs to two adjacent bridges and a sign gantry The approximate cost of the scheme is £4 million

Buxton Water were approached by AE Yates to provide quotations for various hydro-demolition options in November 2017.

From an early stage, Buxton Water worked in close collaboration to provide encapsulation and environmental advice to ensure the hydro demolition works commenced on programme in April 2018.

The Solution

At the tender stage; Potable water supply and used water disposal; without impacting production or affecting other trades were one of the client’s biggest concerns. Using our experience as a specialist contractor; Buxton Water were able to overcome these challenges.

By installing a 250m temporary water main with multiple outlets along the bridge deck allowing equipment to be easily moved between locations. Without the need for HGV road tankers. The risks involved with the interface of plant and pedestrians were removed, also reducing the carbon footprint of the overall scheme.

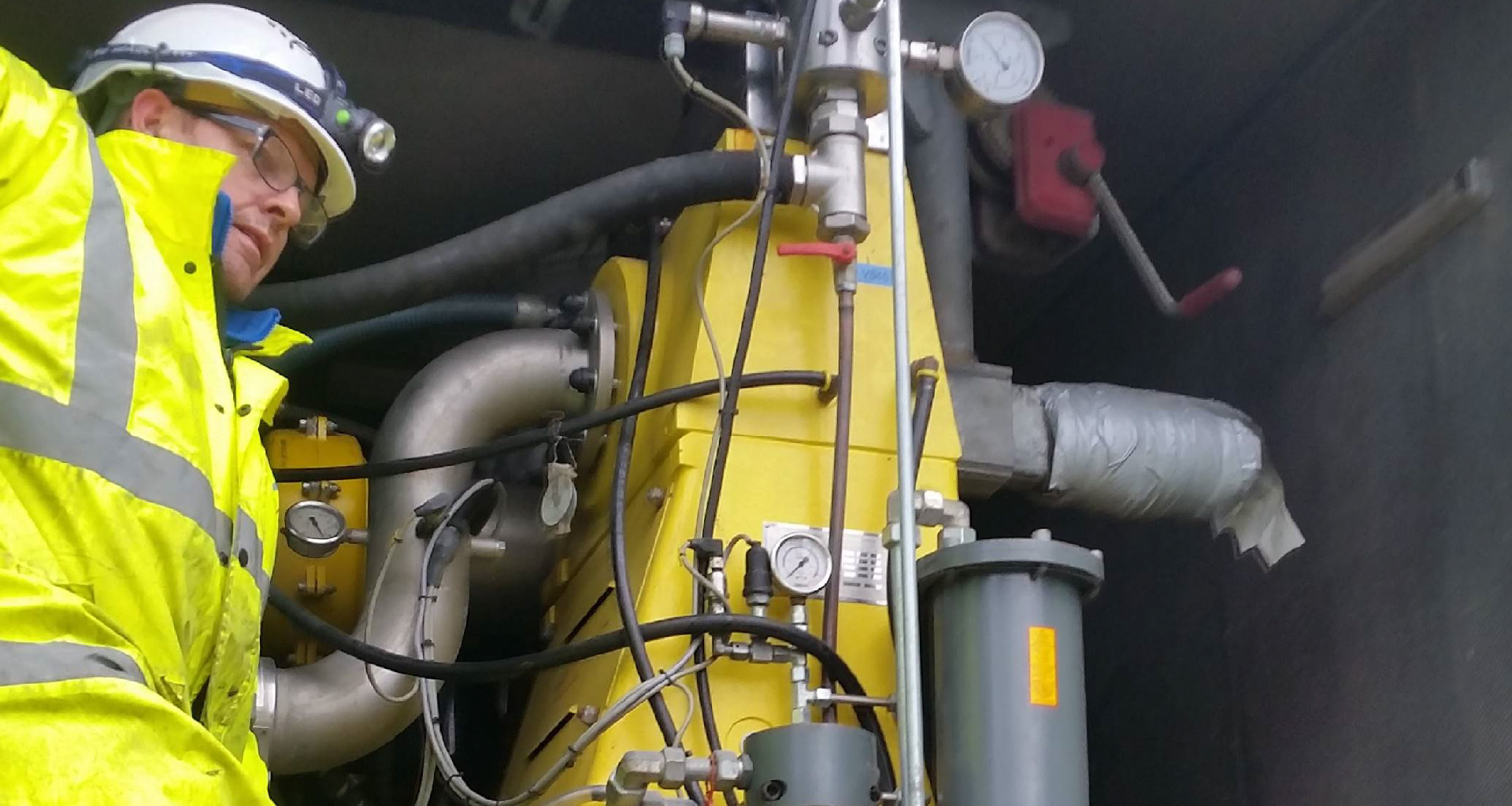

A solution from Siltbuster was employed to consistently clean the used water to a high standard achieved by a 2- stage chemical mixing process followed by gravity settlement to remove any slow settling solids that may have mixed into the water from the concrete.This permitted the cleaned water to be discharged safely and legally into the local drainage system.

Owning and operating one of the UK’s largest robotic fleets, Buxton Water offered a robotic hydro demolition solution – coupled with a 550hp Hammelmann containerised pump package delivering 1200bar at 270L per minute.

The Outcome

Using our specialist equipment and personnel Buxton Water were able to remove 245m³ from 19 separate expansion Joints within the structure. We averaged production rates of 4m³ per day over the course of the job. Buxton Water completed the project without any environmental or safety lost time incidents.

Our initial proposal proved cost effective, environmentally sound and safe whilst having the ability to meet the demands of the programme.

Chris Coleman – Site Agent for AE Yates Limited commented; “Thanks to everyone at Buxton Water for your hard work and efforts over the last few months to get us to this point, although this hasn’t always been the easiest of jobs due to the logistics and its tight nature I am pleased with your performance on site, the lads attitude has been great, I feel when there has been issues we’ve come together well to rectify these.”